Researchers at North Carolina State University have developed a method to print large amounts of metallic glass alloys using 3D technology. This new technique could aid in the construction of more efficient electric motors, higher strength materials, lighter weight structures, better wear-resistant materials, and more.

The full paper is published in the journal Applied Materials Today.

Metallic glass, also known as amorphous metal, lacks the crystalline structure of most metals, so its creation requires rapid cooling to keep the crystalline structure from forming. These limitations previously meant that researchers could cast metallic glasses only a few millimeters thick.

Although the idea of 3D printing metallic glass has been around for more than a decade, this new study is the only work proving that it is possible.

This new technique enabled researchers to cast metallic glass 15 times its original critical casting thickness.

“The layer-by-layer processing during 3D printing provides sufficiently high cooling rates per layer to create BMGs (bulk metallic glass) that are significantly larger than those produced using traditional techniques,” said Zaynab Mahbooba, a doctoral student in NC State’s Department of Materials Science and Engineering and first author of the paper.

How it works

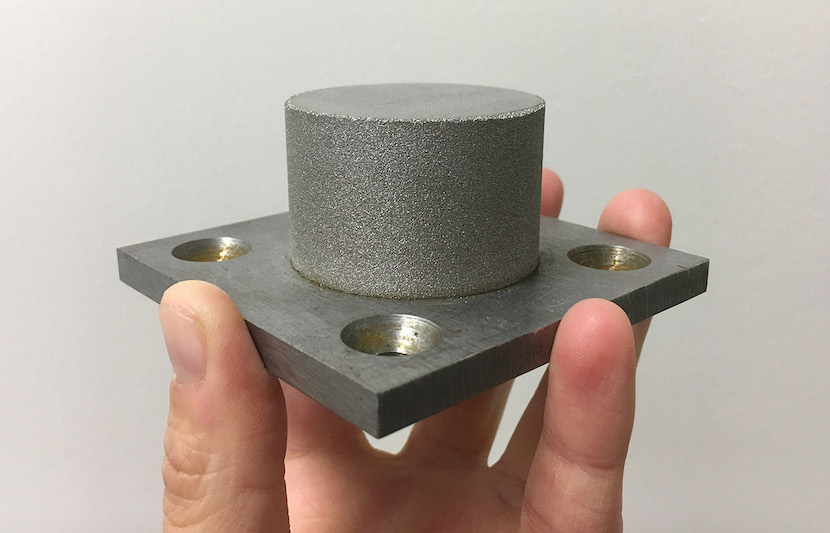

In the study, the researchers used a laser-powder-bed fusion method.

“The process works by first spreading a thin layer of metal powder onto a substrate (in our case the metal was a glass-forming alloy), a laser selectively melts the powder base off cross-sections of the final geometry, and then another layer is spread,” said Mahbooba.

“This process repeats until the final geometry is completed.”

The researchers did have to adjust the laser parameters to accommodate for the unique requirements of metallic glass alloys and to enhance mechanical properties and microstructure, explained Mahbooba.

Through this new technique, the alloy is formed a little at a time, so it cools quickly and retains its amorphous qualities, eventually forming a solid, metallic glass object.

Future implications

This technique could open the door for 3D printing of many other amorphous alloys, but it won’t come immediately.

“There is no reason this technique could not be used to produce any amorphous alloy,” Ola Harrysson, Edward P. Fitts Distinguished Professor of Industrial Systems and Engineering at NC State and corresponding author of the paper, said in a statement.

“One of the limiting factors at this point is going to be producing or obtaining metal powders of whatever alloy composition you are looking for.”

Additionally, the researchers will have to test many alloy compositions to find the right combination of properties.

“For instance, you want to make sure you not only have the desirable electromagnetic properties, but that the alloy isn’t too brittle for practical use,” Mahbooba said in a statement.

As of now, the researchers are working on applying this technique to the construction of electric motors.

“Currently, electric motors are produced using crystalline metals; therefore, to develop BMG-based electric motors we need to design a BMG alloy with optimal material properties for the application (It needs to be magnetic!) and also for additive manufacturing processing,” said Mahbooba.

The study also included Harvey West, Timothy Horn and Christopher Rock of NC State; Lena Thorsson, Mattias Unosson and Peter Skoglund of Sindre Metals; and Evelina Vogli of Liquidmetal Coatings.