A team of researchers from Binghamton University — State University of New York has created a new battery that is both flexible and stretchable. Made entirely from fabric, this new battery is powered by bacteria and so is environmentally friendly.

This new biobattery could potentially be used in wearable electronics one day.

The research is led by Seokheun (Sean) Choi, assistant professor in the Electrical and Engineering Department and director of the Bioelectronics & Microsystems Lab.

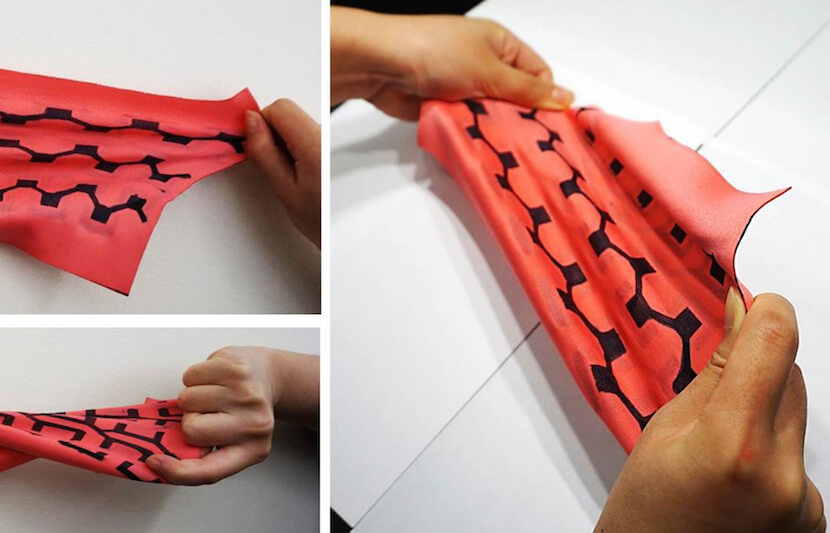

The biobattery’s fabric body allows for it to be stretched and twisted without hindering its capabilities. During the study, the biobattery’s electricity-generating ability remained stable when put through stretching and twisting cycles.

The maximum power that this biobattery produced is similar to that of a series of paper-based microbial fuel cells previously created by Choi and his team.

Textile-based biobatteries are particularly useful and necessary as an energy technology because they are built to provide a more sustainable and eco-friendly alternative to traditional batteries and enzymatic fuel cells. Integrating such a device into wearable electronic devices also makes sense since sweat from the human body can potentially serve as a fuel that can support bacterial viability, adding to its long-term operating potential.

“Textile-based wearable electronics have recently emerged as a technology that promises next-generation, ubiquitous health monitoring,” said Choi.

There are challenges to the technology though, Choi explained.

“[T]here has been a significant challenge in creating a truly self-reliant and stand-alone wearable sensing system that does not rely on an external power source,” he said. “Traditional battery-operated wearable devices cannot realize long-term advanced functionality because of finite energy budgets available from existing batteries. Furthermore, the batteries are too bulky, rigid, and heavy to be integrated in thin, lightweight, and flexible fabric-based devices. Even the latest advances in flexible energy storage devices such as supercapacitor and lithium ion batteries have not been considered as a sole potential platform for self-sustaining, practical use because of their low energy capacity and frequent recharging requirements.”

Health concerns due to microbial cytotoxicity have also stood in the way of the technology’s development, making microbial fuel cells (MFCs) “arguably the most underdeveloped for wearable electronic applications,” said Choi.

Notwithstanding these challenges, Choi believes that the technology has utmost potential for wearable electronics.

“In the literature, reported work on the wearable MFCs was either unavailable or quite limited. However, if we consider that humans possess more than 3.8×1013 bacterial cells compared with 3.0×1013 human cells in their bodies, the direct use of bacterial cells as a power resource interdependently with the human body is conceivable for wearable electronics. The MFCs can be the most suitable power source for wearable electronics because the whole microbial cells as a biocatalyst provide stable enzymatic reactions and long life time.”

The key to success lies in the use of sweat as a potential source of fuel for the MFCs.

“Sweat generated from the human body can be a potential fuel to support bacterial viability, providing the long-term operation of the MFCs,” said Choi. “This stretchable and twistable power device printed directly onto a single textile substrate can establish a standardized platform for textile-based biobatteries and will be potentially integrated into wearable electronics in the future.”

The study is published in Advanced Energy Materials.