After nearly 100 years of satisfying the taste buds of kids and adults, alike, gummi bears may finally have a greater purpose.

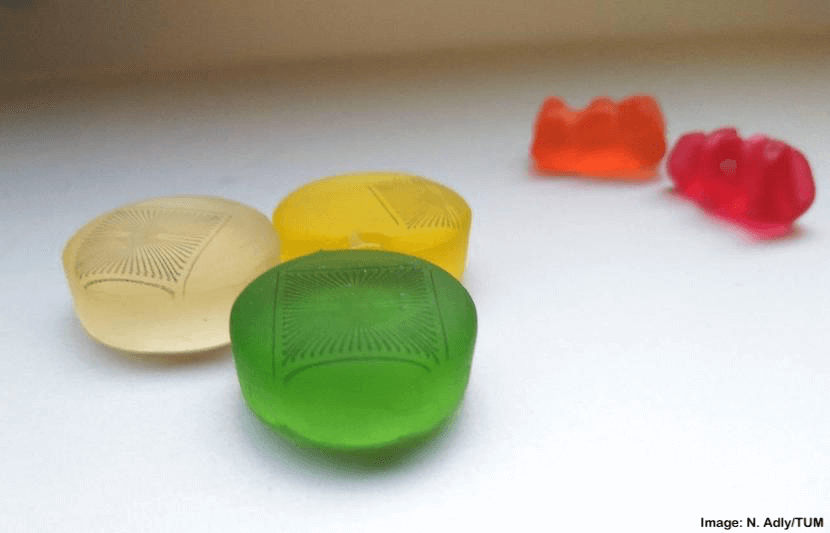

A team of researchers has developed a method to print microelectrode arrays onto gummy candies, gelatin and other soft substrates.

This new method will provide a cheap, fast way to develop microelectrodes that can be used by scientists to study biological changes in the heart and brain, treat disorders of the nervous system, and restore a person’s sensory function.

In this study, researchers from the Technical University of Munich (TUM) and Forschungszentrum Jülich successfully performed inkjet printing onto gummy candies.

A paper describing the study is published in the journal Nature.

Advantages of soft material

The soft texture of the gummies is key to this study.

Traditionally, microelectrode arrays used silicon or glass-based substrates, said Bernhard Wolfrum, a professor of neuroelectronics at TUM and lead author of the study.

But the hard, sharp form of the original microelectrode arrays causes multiple issues.

In a lab, the shape and organization of the cells can be affected by the hardness of the substrate.

In a body, rigid materials can cause cell inflammation and loss of organ functionalities.

Inkjet printing

The inkjet printer used in this study is essentially a high-tech version of one that may be in a home or office. But, instead of using traditional ink, this printer works with carbon-based ink and adds a neutral protective layer to the carbon paths so the sensors don’t pick up any stray signals.

This departs from traditional methods used to create microelectrode arrays.

“Usually, microelectrode arrays are fabricated with optical lithography,” said Wolfrum.

But, those methods are time-consuming and expensive, and require access to specialized laboratories.

Inkjet printing, however, is cheap and quick, and allows scientists to manipulate the design layout of the microelectrode arrays.

“The technique allows us to fabricate carbon-based microelectrode arrays on a variety of soft substrates (such as hydrogels), which is not easily done using conventional microfabrication,” said Wolfrum.

“The possibility to quickly adapt the geometric layout of the interface and materials may help us to develop more efficient devices for cell stimulation and recording.”

Potential applications

Printing microelectrode arrays on soft materials can apply to a wide range of areas.

Not only is the technique useful in fabricating models for research, but it could also be used in the medical field to change the way patients are treated.

“In the future, similar soft structures could be used to monitor nerve or heart functions in the body, for example, or even serve as a pacemaker,” Wolfrum said in a statement.

What’s next?

Before this technique is used to monitor nerve or heart functions in the body, more aspects need to be investigated.

“I believe, for applying the printed devices in vivo, the main aspects that have to be investigated are biocompatibility, long-term stability and reliability and resolution,” said Wolfrum.

“Resolution using inkjet printing is much weaker compared to optical lithography, which might be problematic depending on the particular application.”

For now, the team is focused on efficient printing.

“In my opinion, currently the main advantage of printing functional devices lies in the rapid prototyping capabilities, not necessarily in the final production of devices,” he said.

The researchers are currently working to print more complex 3D microelectrode arrays.

Additionally, they are looking into printable sensors that react to chemical substances, not only fluctuations in voltage.