A group of students at Cuyahoga Community College (Tri-C) in Ohio is using 3D printing techniques to create affordable assistive devices for disabled veterans.

In doing so, the students are applying the knowledge they gain from their 3D Digital Design & Manufacturing Program, a one-year program constructed to prepare students in the field of 3D digital design and 3D printing, or additive manufacturing, technologies.

The program, which was started two years ago, includes a practical course — the Additive Manufacturing Capstone Project — that students take at the end of the program. This one-semester course allows for students to refine and print the prototypes intended to assist disabled people.

“We wanted the students to have a meaningful experience that involved real-world problems,” said Alethea Ganaway, manager of Tri-C’s Additive Manufacturing Program and Ideation Station.

All of the courses available in the program that are project-based are built to incorporate current issues in the Cuyahoga County community, said Ganaway.

“For the Additive Manufacturing Capstone Project, the students must utilize 3D printing for their prototypes,” said Ganaway.

“Because 3D printing has such an impact in the medical industry, we thought it would be great for the Additive Manufacturing Capstone students to work with veterans.”

According to The Plain Dealer, student Christopher Wiersma created the Garden Buddy, a set of assistive tools, to help a paralyzed patient spend more time exploring his passion of gardening.

Student Mark Lettieri created the Fisherman’s Gauntlet, a spring-loaded fishing pole, to help veterans without motor control fish again without having to cast a line.

To help veterans turn through the pages of a book once again, Tyler Tomazic and Eric Szabo manufactured the Easy Easel. Szabo later developed another helpful reading device called the UFO Page Turner, which is applicable for both books and touchscreens.

Student Jarrod Koch empathized with the disabled veterans, for he had become paralyzed in an accident a few years earlier. Because he was accustomed to similar everyday struggles as the paralyzed veterans, he developed Add-it Hands, a device that can assist in various ways, from shaving to eating.

Khushbu Patel also created an effective, inexpensive device to help the disabled eat their food.

This recent group of students, who took the Capstone course in summer of 2017, was the second group to work with veterans.

“While 3D printed is not the answer for everyone or everything, 3D printing is a great resource in the medical industry,” said Ganaway.

“Among other things, it has the ability to allow medical professionals to create patient specific devices. The students work with the veterans and create a device that helps them to overcome their unique challenges. Also, many of these devices can be printed for under ten dollars.”

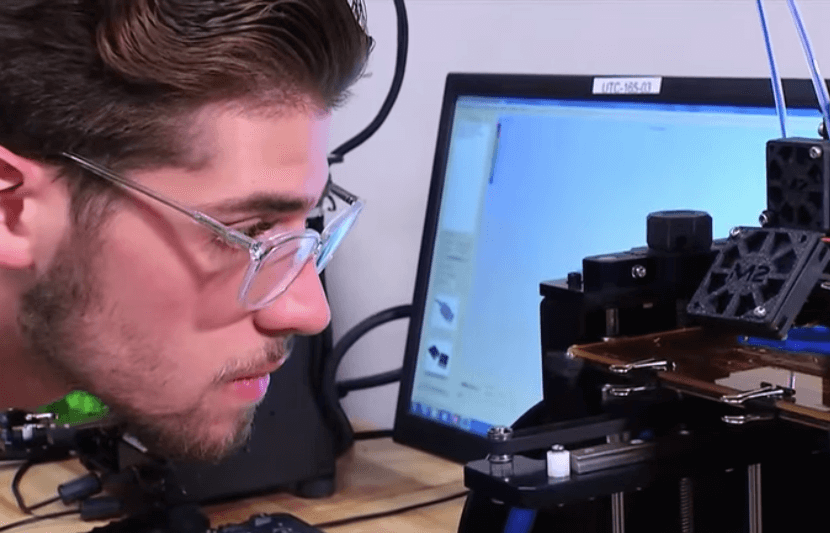

To turn the students’ ideas into workable assistive devices, they had to construct cardboard and digital models that could be programmed into a 3D printer.

The opportunity to work with and assist veterans and others in the community teaches students more than they can learn in a classroom.

“The students get real-world, invaluable experience,” said Ganaway.

“They learn how to use critical thinking and analytical skills to solve a problem that affects people in the community. It also allows them utilize their skills in reverse engineering, solid modeling and 3D printing. This project is a great addition to their portfolio that they can share with future employers.”

As for the future of this program, Tri-C intends to continue its work with veterans.

Since the Capstone course is only one-semester long, the students don’t have a great amount of time to refine their prototypes, said Ganaway.

“We (Tri-C) are looking at how to have a continuing partnership with the VA (Veterans Affairs) that engages the veterans longer than a semester,” she said.

“Therefore, additional adjustments can be made to the device if needed and to determine how the veterans are impacted overtime.”