A team of chemical engineering researchers from the University of Sydney and Nanyang Technological University in Singapore have developed rechargeable zinc-air batteries that could replace lithium-ion batteries as the power source for electronic devices. Zinc-air batteries, as the name suggests, use zinc metal and oxygen as the source of their power.

Zinc-air batteries have many advantages over lithium-ion batteries. Unfortunately, the use of zinc-air batteries have been limited so far to low-power devices, such as hearing aids, film cameras, and railway signal devices. The limitation is imposed by the difficulty in recharging zinc-air batteries caused, to date, by the lack of electrocatalysts that are capable of successfully reducing and generating oxygen during the process of discharging and charging of a battery.

That limitation has now been removed by the new 3-step method for rechargeable zinc-air batteries developed by the research team led by Yuan Chen, professor of chemical engineering at the University of Sydney’s School of Engineering and Information Technologies.

The research is published in Advanced Materials.

“Zinc-air batteries assembled in our lab have achieved 60 charge/discharge cycles over 120 hours,” Chen told The University Network (TUN). “In comparison, common lithium-ion batteries have the cycle durability of 400 to 1200 cycles.”

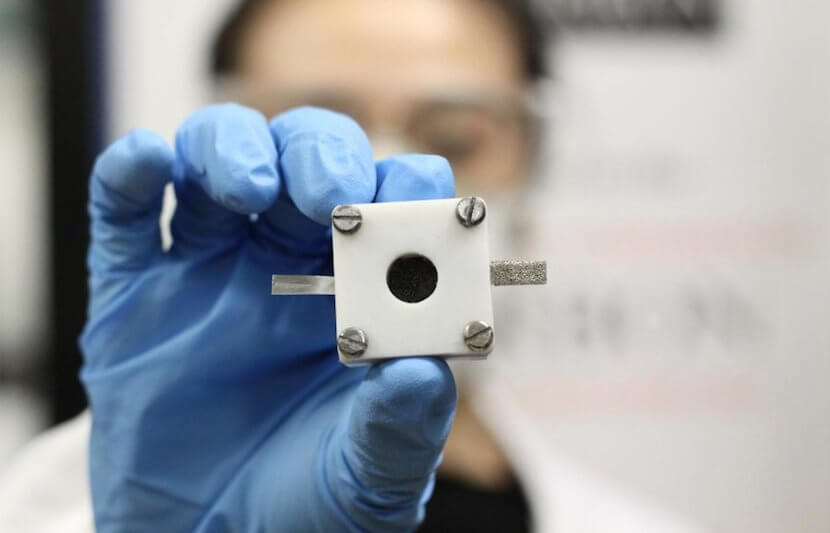

The researchers used a 3-step method that involves the “simultaneous control” of composition, size, and metal oxide crystallinity to produce “bifunctional oxygen electrocatalysts” that can be used to build rechargeable zinc-air batteries.

“Up until now, rechargeable zinc-air batteries have been made with expensive precious metal catalysts, such as platinum and iridium oxide. In contrast, our method produces a family of new high-performance and low-cost catalysts,” Chen said in a statement.

The team’s method uses metals that are available in abundance, such as nickel, iron, and cobalt, for its rechargeable zinc-air batteries.

Chen maintains that the team’s rechargeable zinc-air batteries are superior to lithium-ion batteries for many reasons. As he explained to TUN:

“There are several benefits of rechargeable zinc-air batteries. (1) The energy density is much higher so they last longer after each charge cycle. (2) Zinc is a much abundant element on earth compared to lithium and other precious metals. We don’t need to worry about the shortage of zinc supply. Thus, zinc-air batteries are more sustainable. (3) Zinc is much cheaper than lithium. The iron and cobalt based air catalysts are also much cheaper than precious metal based catalysts. The price of zinc-air batteries is expected to be much lower than that of lithium-ion batteries. (4) Zinc is much more stable when exposed to air compared to lithium. Zinc-air batteries won’t get on fire so easily. They are much safer than lithium-ion batteries.”

The team hopes that the clear advantages of rechargeable zinc-air batteries will help replace lithium-ion batteries in popularity and usage.

“This is our goal, especially for applications where high energy storage capacity is required, for example, electric cars,” Chen told TUN.

While the team still has to improve the performance of the rechargeable zinc-air batteries and resolve some technological issues, Chen is confident of mass-producing rechargeable zinc-air batteries that will overtake lithium-ion batteries as the energy choice. “It took more than 20 years to develop lithium-ion batteries into successful commercial products,” he told TUN. “We hope to see successful commercial rechargeable zinc-air batteries in 5 to 10 years time.”

The research team includes Li Wei, Shengli Zhai, Hongwei Liu, Xuncai Chen, Zheng Zhou, Yaojie Lie, and Zongwen Liu from the University of Sydney, and H. Enis Karahan and Shengli Zhai who are affiliated with the University of Sydney as well as Nanyang Technological University.