Engineers at the University of São Paulo and Princeton have unveiled a breakthrough in cement recycling, creating a low-carbon alternative that retains the strength and workability of conventional Portland cement. This innovation could dramatically reduce the carbon footprint of the construction industry.

Engineers at the University of São Paulo and Princeton University have introduced a revolutionary method for recycling cement waste into a sustainable, low-carbon alternative that matches traditional Portland cement in strength and performance. This innovative process could substantially reduce the massive carbon footprint of the cement industry, which is responsible for approximately 8% of global carbon emissions.

“Construction waste typically ends up either in a landfill, or, if it’s recycled, will be used in low-grade applications such as in pavements or in soils,” Sérgio Angulo, a professor of civil and urban construction engineering at the University of São Paulo, who led the research, said in a news release. “It’s exciting to show that we can, in fact, recycle this recovered cement waste into a high-quality application.”

The research, published in ACS Sustainable Chemistry & Engineering, highlights that mixtures containing up to 80% recycled cement demonstrate strength similar to conventional Portland cement while emitting significantly less carbon dioxide.

If fully implemented, this approach could slash emissions from the cement industry by up to 61%, a vast improvement over the 9% reduction projected by traditional clinker replacement strategies.

“The leap forward here is that you can now get short- and long-term properties that are essentially the same as Portland cement by itself with a low-carbon alternative overwhelmingly composed of recycled materials,” added co-author Claire White, a professor of civil and environmental engineering and the Andlinger Center for Energy and the Environment at Princeton.

The recycling method centers on heating pulverized concrete waste to 500 degrees Celsius, effectively dehydrating the cement powder and restoring its binding properties. This thermoactivation process avoids the decomposition of carbonate components, which would otherwise release additional CO2. The result is a durable, low-carbon binder that can even outperform other emerging low-carbon cements.

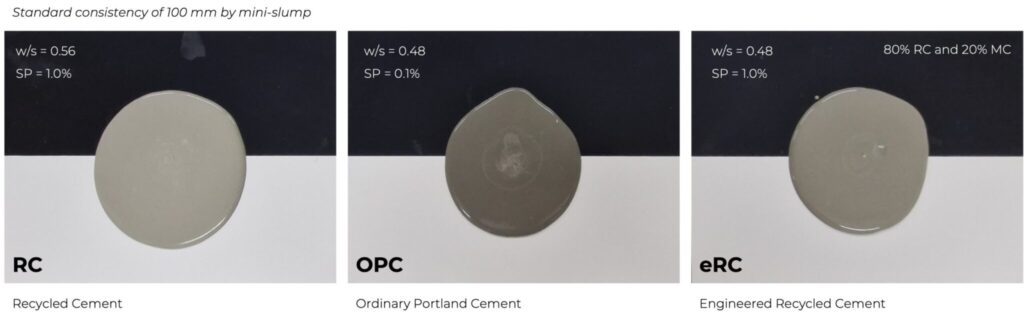

Caption: A comparison of recycled cement by itself (left), ordinary Portland cement (middle), and the researchers’ optimized blend of recycled cement and finely ground Portland cement (right), after the addition of water.

Credit: Mateus Zanovello/University of São Paulo

While promising, several challenges lie ahead for broad adoption. Technological advancements in sorting and processing demolition waste are necessary, alongside updates to building codes to accommodate performance-based standards rather than fixed compositions.

“In Brazil, we are already beginning to implement performance-based standards for non-structural building envelopes and floors,” added Angulo. “Updating construction codes is important for allowing innovation in the building sector.”

This milestone in sustainable construction results from an ongoing collaboration initiated when Angulo visited White’s group at Princeton in 2023. Their combined expertise in advanced characterization techniques and eco-efficient materials has proven fruitful, offering new perspectives and capabilities in their respective fields.

“This collaboration has had benefits in both directions,” White added. “Sérgio’s brought his domain knowledge, my group has brought our expertise in advanced characterization techniques, and together, we’ve been able to tackle some of the biggest challenges about this material.”

The study was supported by Brazil’s National Institute on Advanced Eco-Efficient Cement-Based Technologies and Princeton’s Carbon Mitigation Initiative.

Source: Princeton Engineering